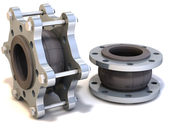

According to their physical properties, most metals expand with increasing temperatures and contract with decreasing temperatures. In pipeline systems, this phenomenon causes a variation in the length of the individual sections of the pipeline. As pipelines are normally anchored at least on two connection points, any variation in length will result in thermal strain in the material and enhanced forces and moments at these terminal points. As far as possible, one will utilize the inherent flexibility of a pipeline to compensate for the pipe expansion (natural compensation). Should the expansion, however, exceed the inherent flexibility of the pipe, expansion joints are necessary to compensate these movements. Additionally, mechanical vibrations of pumps, compressors, turbines and motors should be dampened to avoid any damage to adjoining pipelines, their supports or any installed instruments. Forces and moments on nozzles of compressors, turbines, vessels and other plant components are limited and must not be exceeded. In all these cases, expansion joints can be utilized.

The central component of each expansion joint is the metal bellows (exceptions are rubber expansion joints.) that, due to its shape and thin wall, acts as a spring. The bellows, however, have to meet the following basic criteria to qualify for its use as an expansion element:

- withstand the operating and test conditions (pressure, temperature) of the pipe system,

- ensure corrosion resistance against internal (flow) and external (atmospheric) conditions,

- provide sufficient flexibility to compensate thermal expansion and mechanical vibrations with the requested durability (life expectancy)

- include sufficient squirm stability.